| Model No. |

SM-35 DA - M/E |

SM-35

TDE |

SM-35 TP |

SM-45 DA-M/E |

SM-45 TDE |

SM-45 TP |

| Drilling Capacity ( steel (60kg./sq.mm) /cast Iron) |

Ø 35 / Ø 42 |

Ø 35 / Ø 42 |

Ø 35 / Ø 42 |

Ø 45 / Ø 50 |

Ø 45 / Ø 50 |

Ø 45 / Ø 50 |

| Tapping capacity ( steel (60kg./sq.mm) /cast Iron) |

…….. |

M 24 x M 30 |

M 24 x M 30 |

…….. |

M 36 / M 42 |

M 36 / M 42 |

| Minimum size of tapping Operation |

…….. |

M8 |

M8 |

…….. |

M10 |

M10 |

| Spindle |

|

|

|

|

|

|

| Spindle Nose Taper ( T ) |

MT-4 (Female) |

MT-4 (Female) |

MT-4 (Female) |

MT-5 (Female) |

MT-5 (Female) |

MT-5 (Female) |

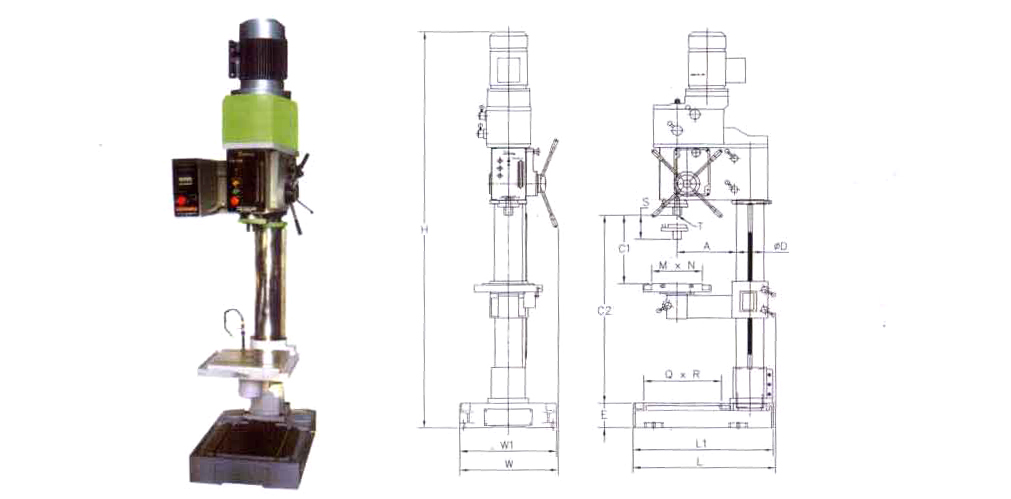

| Total Sleeve (Spindle) Stroke ( S ) |

150 |

150 |

150 |

200 |

200 |

200 |

| Nos.of Spindle Speeds |

8 |

8 |

8 |

8 |

8 |

8 |

| Speed Range ( with 2 Step Gear Box) |

100 - 280 - 400 - 1000 |

50 - 125 - 180 - 500 |

50 - 125 - 180 - 500 |

56 - 160 - 224 - 630 |

32 - 80 - 112 - 315 |

32 - 80 - 112 - 315 |

| |

200 - 560 - 800 - 2000 |

100 - 250 - 355 - 1000 |

100 - 250 - 355 - 1000 |

125 - 315 - 450 - 1250 |

64 - 160 - 224 - 630 |

64 - 160 - 224 - 630 |

| Spindle Feed |

Auto + Manual |

Auto + Manual |

Auto+Manual/Lead Scr. |

Auto + Manual |

Auto + Manual |

Auto+Manual / Lead Scr. |

| No. of Autofeeds |

3 |

3 |

…….. |

4 |

4 |

…….. |

| G) Autofeeds for Spindle |

0.1 / 0.2 / 0.3 |

0.1 / 0.2 / 0.3 |

…….. |

0.1 / 0.2 / 0.3 / 0.36 |

0.1 / 0.2 / 0.3 / 0.36 |

…….. |

| Auto Feed Engagement (normal) |

Electro-magnetic clutch |

Electro-magnetic clutch |

…….. |

Electro-magnetic clutch |

Electro-magnetic clutch |

…….. |

| Auto Feed Engagement (optional) |

Mechanical clutch |

…….. |

…….. |

…….. |

…….. |

…….. |

| Spindle Axis to column Face ( throat ) ( A ) |

300 |

300 |

300 |

350 |

350 |

350 |

| Spindle Nose to work Table (min./ max)(C1) |

0 / 720 |

0 / 720 |

0 / 720 |

0 / 730 |

0 / 730 |

0 / 730 |

| Spindle Nose to Base Plate (max)( C2) |

1120 |

1120 |

1120 |

1150 |

1150 |

1150 |

| Cloumn Diameter (O.D.)( Ø D ) |

Ø 124 |

Ø 124 |

Ø 124 |

Ø 165 |

Ø 165 |

Ø 165 |

| Clamping Area on work Table( M x N ) |

320 x 320 |

320 x 320 |

320 x 320 |

370 x 370 |

370 x 370 |

370 x 370 |

| Clamping Area on Base Plate( Q x R ) |

320 x 380 |

320 x 380 |

320 x 380 |

450 x 450 |

450 x 450 |

450 x 450 |

| T Slots on Work Table ( Size / Pitch / Nos.) |

14 / 200 / 2 |

14 / 200 / 2 |

14 / 200 / 2 |

14 / 240 / 2 |

14 / 240 / 2 |

14 / 240 / 2 |

| T Slots on Base Plate (Size / Pitch / Nos.) |

18 / 200 / 2 |

18 / 200 / 2 |

18 / 200 / 2 |

18 / 320 / 2 |

18 / 320 / 2 |

18 / 320 / 2 |

| Motor 3Ph. TEFC (KW / HP) |

1.1 / 1.5 - 1.5 / 2 |

1.1 / 1.5 - 1.5 / 2 |

1.1 / 1.5 - 1.5 / 2 |

1.5 / 2 - 2 / 3 |

1.5 / 2 - 2 / 3 |

1.5 / 2 - 2 / 3 |

| Motor RPM |

1500 - 3000 |

750 - 1500 |

750 - 1500 |

1500 - 3000 |

750 - 1500 |

750 - 1500 |

| Electric Supply |

415V,3Ph,50Hz |

415V,3Ph,50Hz |

415V,3Ph,50Hz |

415V,3Ph,50Hz |

415V,3Ph,50Hz |

415V,3Ph,50Hz |

| Control Voltage |

220V,1Ph,50Hz |

220V,1Ph,50Hz |

220V,1Ph,50Hz |

220V,1Ph,50Hz |

220V,1Ph,50Hz |

220V,1Ph,50Hz |

| Overall size of Base Plate ( L1 x W1 x H 1) |

650 x 420 x 125 |

650 x 420 x 125 |

650 x 420 x 125 |

830 x 570 x 125 |

830 x 570 x 125 |

830 x 570 x 125 |

| Drive |

Gear |

Gear |

Gear |

Gear |

Gear |

Gear |

| Overall size of Machine( W x L x H ) |

500 x 900 x 2250 |

500 x 900 x 2250 |

500 x 900 x 2250 |

570 x 830 x 2425 |

570 x 830 x 2425 |

570 x 830 x 2425 |

| Machine Weight in Kgs. |

400 |

400 |

400 |

550 |

550 |

550 |